Dilatation seals, also known as expansion joints or expansion seals, are mechanical devices designed to accommodate the expansion and contraction of various structural elements, such as buildings, bridges, pipelines, and industrial equipment, due to temperature variations, seismic activity, or other external factors. These seals play a crucial role in preventing damage and maintaining the structural integrity of these components by allowing them to expand and contract without causing stress or deformation.

Here is a more detailed and comprehensive description of dilatation seals:

1. Purpose:

Dilatation seals serve a vital purpose in a wide range of applications where materials and structures are subjected to thermal fluctuations or movement. Their primary function is to absorb, control, and mitigate the effects of expansion and contraction, as well as movements resulting from seismic activity, settlement, or other environmental factors.

2. Types:

Dilatation seals come in various types to suit the specific needs of different applications. The most common types include:

- Metallic Expansion Joints: These are made of metal components like stainless steel or other alloys. They are used in high-temperature applications and can withstand substantial pressure.

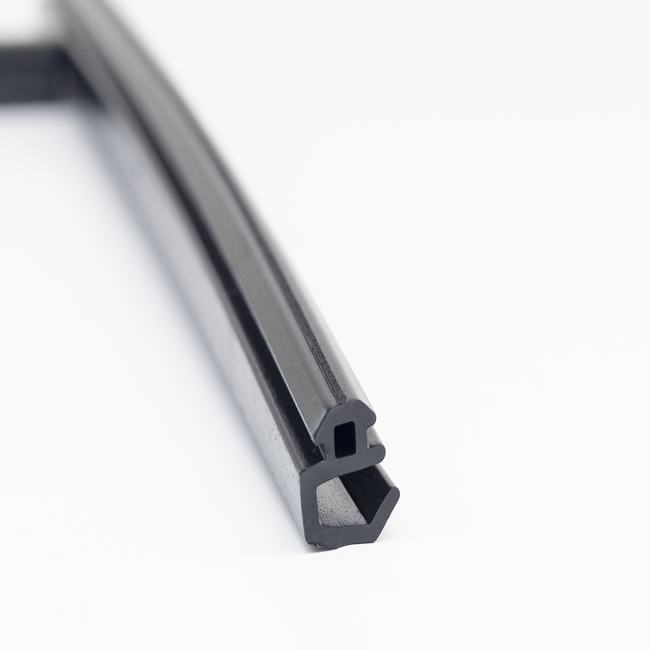

- Rubber Expansion Joints: Composed of rubber or elastomeric materials, these are ideal for applications where flexibility and vibration damping are required.

- Fabric Expansion Joints: Typically used in ducting systems, fabric expansion joints are made of woven or non-woven materials that can handle both axial and lateral movement.

- Pipe Expansion Joints: These are designed for pipelines and other fluid-handling systems and come in various designs, including bellows expansion joints, gimbal expansion joints, and more.

- Bridge Expansion Joints: Specifically engineered for bridges, these joints allow for the expansion and contraction of bridge components, reducing stress on the structure.

3. Components:

A dilatation seal typically consists of several essential components, such as bellows or expansion elements, flanges or connection points, and hardware for attachment. The design and materials used depend on the specific application and environmental conditions.

4. Functionality:

When subjected to temperature changes, structures naturally expand or contract. If this thermal movement is not adequately accommodated, it can lead to structural damage, such as cracks, leaks, or failures. Dilatation seals are strategically placed at key locations within the structure to absorb these movements. When the structure expands, the seal compresses, and when the structure contracts, the seal expands, thus relieving stress and ensuring the structural elements remain intact.

5. Installation and Maintenance:

Proper installation and regular maintenance are crucial for the effective operation of dilatation seals. Installation must follow the manufacturer’s guidelines and industry standards. Maintenance includes inspections for wear and tear, damage, or corrosion, and replacing or repairing components as needed to ensure the continued functionality of the seal.

6. Industries and Applications:

Dilatation seals find use in a wide array of industries and applications, including:

- Building and construction: To accommodate the movement of building structures.

- Industrial processes: In pipelines, machinery, and equipment to handle thermal expansion and contraction.

- Transportation: In bridges, highways, and railways to manage the movement of structures.

- Energy: In power plants and utilities to compensate for temperature changes in pipes and equipment.

- HVAC systems: In heating, ventilation, and air conditioning systems to reduce vibration and noise.

- Aerospace: In aircraft and aerospace components to withstand the rigors of flight.

7. Benefits:

The use of dilatation seals offers several advantages, including:

- Extended service life for structures and components.

- Improved safety by preventing structural damage.

- Reduced maintenance and repair costs.

- Enhanced operational efficiency in various industries.

In conclusion, dilatation seals are critical components in modern engineering and construction, allowing for the safe and efficient functioning of structures and systems in the face of environmental challenges such as temperature fluctuations and movement. Their versatility and effectiveness make them indispensable in a wide range of applications across various industries. Proper selection, installation, and maintenance of these seals are essential to ensure their long-term performance and the integrity of the systems they protect.