Concrete pipe seals, also known as concrete pipe gaskets or concrete pipe joint seals, are essential components used to create watertight and secure connections between concrete pipes in sewer and drainage systems, stormwater management, and other infrastructure projects. These seals play a critical role in preventing leaks, infiltration of groundwater, and the escape of contaminants from the pipes. Here is an overview of concrete pipe seals, their types, features, applications, and benefits:

Types of Concrete Pipe Seals:

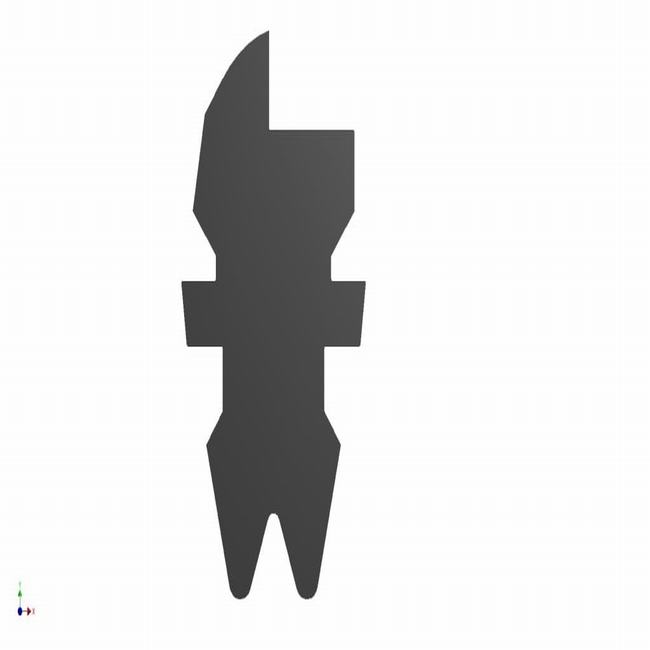

- Rubber Ring Seals: These are the most common type of concrete pipe seals. They consist of a circular rubber ring, often made of EPDM or neoprene, that is placed in the groove of the pipe socket. When two concrete pipes are joined, the rubber ring creates a watertight seal.

- Mastic Seals: Mastic seals are adhesive compounds that are applied to the spigot end of the concrete pipe before joining. They provide an additional layer of sealing protection when the pipes are connected.

- Compression Seals: Compression seals are designed to compress and expand as pipes are joined, ensuring a secure and flexible seal. They are often used in applications where joint movement may occur.

Features of Concrete Pipe Seals:

- Material Durability: Concrete pipe seals are typically made from high-quality rubber compounds, such as EPDM or neoprene, which are resistant to aging, weathering, and chemicals.

- Watertight Seal: These seals are specifically designed to create a watertight connection between concrete pipes, preventing leaks and infiltration.

- Flexibility: Concrete pipe seals are flexible and can accommodate minor misalignments, pipe movements, and settlement, maintaining the integrity of the seal.

- Easy Installation: Installing concrete pipe seals is a straightforward process, often requiring only manual pressure to secure the seal.

Applications of Concrete Pipe Seals:

Concrete pipe seals are widely used in various infrastructure and construction applications, including:

- Sewer and Drainage Systems: Concrete pipe seals are essential in municipal sewer and drainage systems to prevent groundwater infiltration and protect against leaks.

- Stormwater Management: They are used in stormwater management systems, including culverts and storm drains, to ensure proper water flow and prevent erosion.

- Wastewater Treatment Plants: These seals are employed in wastewater treatment plants to seal pipe connections and prevent the escape of wastewater contaminants.

- Irrigation Systems: Concrete pipe seals are used in agricultural irrigation systems to maintain water flow and prevent water loss.

- Culverts and Bridges: They are used in culverts and bridge applications to provide secure and watertight connections in drainage systems.

Benefits of Concrete Pipe Seals:

- Leak Prevention: The primary function of concrete pipe seals is to prevent leaks and infiltration, which is critical for the integrity of sewer and drainage systems.

- Longevity: Concrete pipe seals are durable and have a long service life, reducing maintenance and replacement costs.

- Environmental Protection: By preventing the escape of contaminants, these seals help protect the environment and public health.

- Easy Maintenance: When maintenance is required, replacing concrete pipe seals is a relatively simple and cost-effective process.

In summary, concrete pipe seals are essential components in the construction and maintenance of infrastructure systems. Their durability, flexibility, and ability to create watertight seals make them crucial for ensuring the proper functioning of sewer, drainage, and stormwater management systems.